|

Products |

|

Contact Us |

Address: Xichong, Sixiang Village, Zhongtang Town, Dongguan City, Guangdong Province |

Tel:

0086-757-8682 1877

|

Fax: |

|

|

|

|

|

Your position : Products

> Dongshang Board

|

Dongshang Board

|

|

|

Ⅰ Brief Introduction

Dongshang Board is a kind of green building material of environmental protective and high-tech calcium silicate board. It uses the siliceous and calcareous material as its main raw material; more than 50% of material ingredients are the same as the principal constituent of granite, and that 20% the same as marble. Dongshang Board has properties like of fireproof, anti-moisture, lightweight, high impact strength and so on. ecause of its excellent product features, Dongshang Board is particularly applicable to places with high requirement for fire rating and damp proof. Such as shopping mall, hotel, real estate, office building, commercial building, theater, hospital, school, stadium, airport, station, tunnel, research institution, laboratory, industry building, house decoration and so on. Dongshang Board is a kind of green building material of environmental protective and high-tech calcium silicate board. It uses the siliceous and calcareous material as its main raw material; more than 50% of material ingredients are the same as the principal constituent of granite, and that 20% the same as marble. Dongshang Board has properties like of fireproof, anti-moisture, lightweight, high impact strength and so on. ecause of its excellent product features, Dongshang Board is particularly applicable to places with high requirement for fire rating and damp proof. Such as shopping mall, hotel, real estate, office building, commercial building, theater, hospital, school, stadium, airport, station, tunnel, research institution, laboratory, industry building, house decoration and so on.

Ⅱ Properties

Fire Rating

Gold Element Board accords with standard GB8624 and generates national incombustible Class A1. It has excellent fire rating performance and will not transfer flame or release any toxic smoke in case a fire breaks out. |

|

Waterproof and Anti-moisture | Even in open areas and high humidity environment, Gold Element Board still can maintain stable performance, keep low rate of inflation and shrinkage and have waterproof and anti-moisture and frost prevention properties. It becomes an ideal material for kitchens, bathrooms, and other internal and external building walls. |

|

Anti-corrosion and Anti-moth | The board also has good anti-aging, anti-moth, anti-mould and anti-corrosion effects. |

|

Light weight, High impact strength and Anti-sagging

Gold Element Board is in light weight, high strength, toughness and easy to carry and construct.

| Sound Isolation |

| The board has good sound isolation function which can meet the requirements of various sound isolation walls and barriers. |

|

|

| Heat insulation |

| Owing to its low thermal conductive index and excellent insulation property, the board can be widely used in buildings with high requirement on heat insulation. |

|

|

| High Accuracy |

| Using world first-class production line and advanced equipments, adding strict quality control management system of the company, the products are almost produced with no error and the quality is quite stable. |

|

|

| Fast Installation |

| To use this kind of board in construction is fairly convenient, because it is smooth and there is no need of plastering. And it is quite easy to do secondary processing like drilling, planning and sawing, as well as other surface decoration dealings. |

|

|

Ⅲ Standard Specification

2440×1220×4~22mm

Ⅳ Performance Parameters

1.Board Tolerance

Board Thickness

(mm) |

Length

(mm) |

Width

(mm) |

Thickness Tolerance (mm) |

Edge Flatness

(mm/m) |

Surface Flatness

(mm/m) |

Squareness

(mm/m) |

| 5~8 |

±2 |

±2 |

±0.3 |

≤2 |

≤3 |

±3 |

| 9~12 |

±0.5 |

| 12以上 |

±0.8 |

|

2.Physical Properties

| Item |

Index |

Unit |

| Density |

1.20~1.30 |

g/cm3 |

| Thermal Conductivity |

≤0.25 |

W/m·k |

| Moisture Content |

≤10 |

% |

| Moisture Movement |

≤0.25 |

% |

| Heat Shrinkage |

≤0.5 |

% |

| Incombustibility |

Comply with Standard GB8624-2006 Class A1 |

/ |

| Bending Strength |

≥Ⅲ |

Grade |

Cross and Parallel

Strength Ratio |

≥58 |

% |

| Fire Resistance |

GB/T 9978-2008(1-9)

2 hours |

Hour |

|

Ⅴ Product Application Systems and Installation Instruction

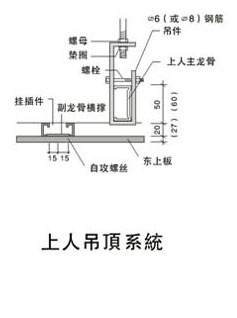

1. U-shaped Keel Ceiling System

First hanging the main keels on the ceiling by using the hanger rod and other base parts, leaving a gap about 900-1000 mm between each two main keels and making sure that all the make keels are on the same level. The distance of the fixed points is also 900-1200 mm. Second, fixing the vice keels with pendants and leaving a distance of 610 mm between each two vice keels. Using tools to fix the main keels and the distance between the joints is 1220 mm .The connections must be staggered arranged if the keel is too short and there is need to add another keel. First hanging the main keels on the ceiling by using the hanger rod and other base parts, leaving a gap about 900-1000 mm between each two main keels and making sure that all the make keels are on the same level. The distance of the fixed points is also 900-1200 mm. Second, fixing the vice keels with pendants and leaving a distance of 610 mm between each two vice keels. Using tools to fix the main keels and the distance between the joints is 1220 mm .The connections must be staggered arranged if the keel is too short and there is need to add another keel.

The fixed board and the vice keels must be in vertical. The distance between each two vertical arranged self-sapping screw installed on the retaining board is 250-300mm. The screw is 15 mm away from the board edge, 50mm away from the board angle.

The board fixed on the ceiling means it completely independent from the wall. This kind of ceiling will not be affected and interacted by the changes of the wall. For places of higher fireproof, dustproof, heat and sound insulation requirements, we can fix the keels and boards with the walls around the ceiling so that connecting the walls and ceiling into a structure as one.

For U-shaped keel ceiling system, the large size ceiling should be divided into many areas; each area can not be more than 60 square meters. |

|

|

|

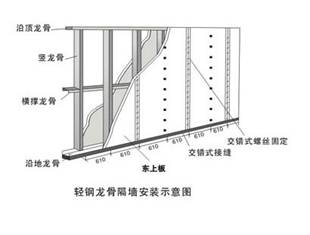

2.Dongshang Board Partition System

Before installing the board, you must sign the exact locations of U shaped stud according to the design drawing, as well as the exact locations of windows, sanitation facilities and pipelines; Before installing the board, you must sign the exact locations of U shaped stud according to the design drawing, as well as the exact locations of windows, sanitation facilities and pipelines;

In the process of installing the keels, the shaft keels should be followed by the same direction and arranged successively, and the horizontal distance between every two keels is 610mm, especially ensuring that shaft keels are in vertical direction;

Boards should be linked without any gap but leave a distance of 3mm between the board and the ground. The distance between each two vertical arranged self-tapping screws which installed on the retaining board is 250-300mm. The self-tapping screw is 15mm away from the board edge, 50mm away from the board angle, and the pin finned should be immersed into the board 1mm.

|

|

|

Lightweight Fireproof Ceiling:

|

|

|

Lightweight Fireproof Partition:

|

|

|

Steel Column Fire Protection System:

|

|

|

Self-braced Fire-rating Pipe

|

Upper Blockage of Fire Rolling Curtain

|

|

|

|

|

|